Heigham, Norwich

Overview

The Heigham Wastewater Treatment Works (WwTW) project is a vital investment by Anglian Water to meet the growing water demands of Norwich, a city projected to see its population reach one million by 2034. For over a century, Heigham WwTW has supplied drinking water to approximately 200,000 residents but with a rising population and increasing environmental pressures, a resilient solution was required to ensure a sustainable supply of potable water.

This initiative is part of Anglian Water’s broader strategy to enhance water management while protecting the River Wensum, a designated Special Area of Conservation (SAC). The project addresses both the environmental and operational challenges of supplying water in one of the UK’s driest regions.

What We Did

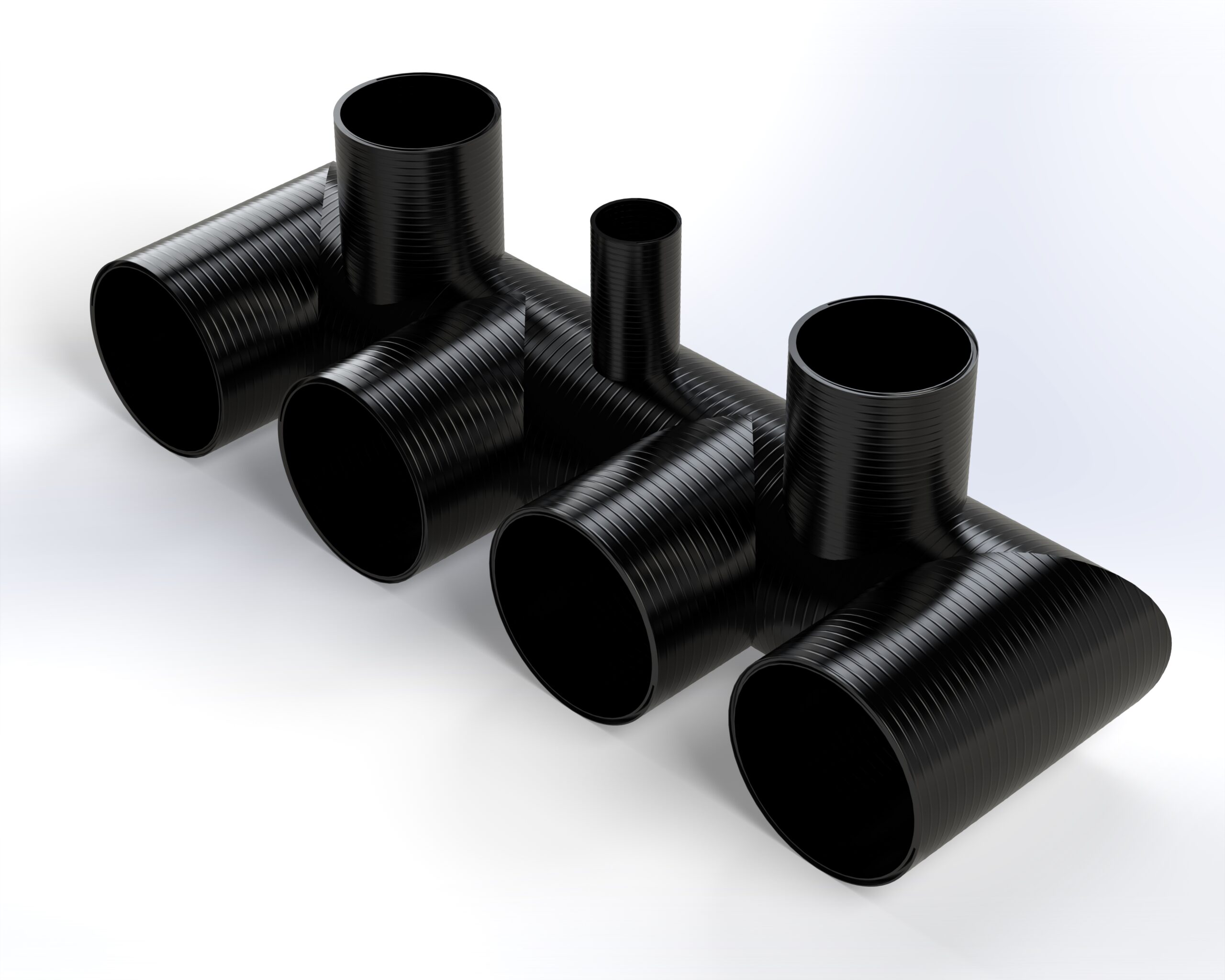

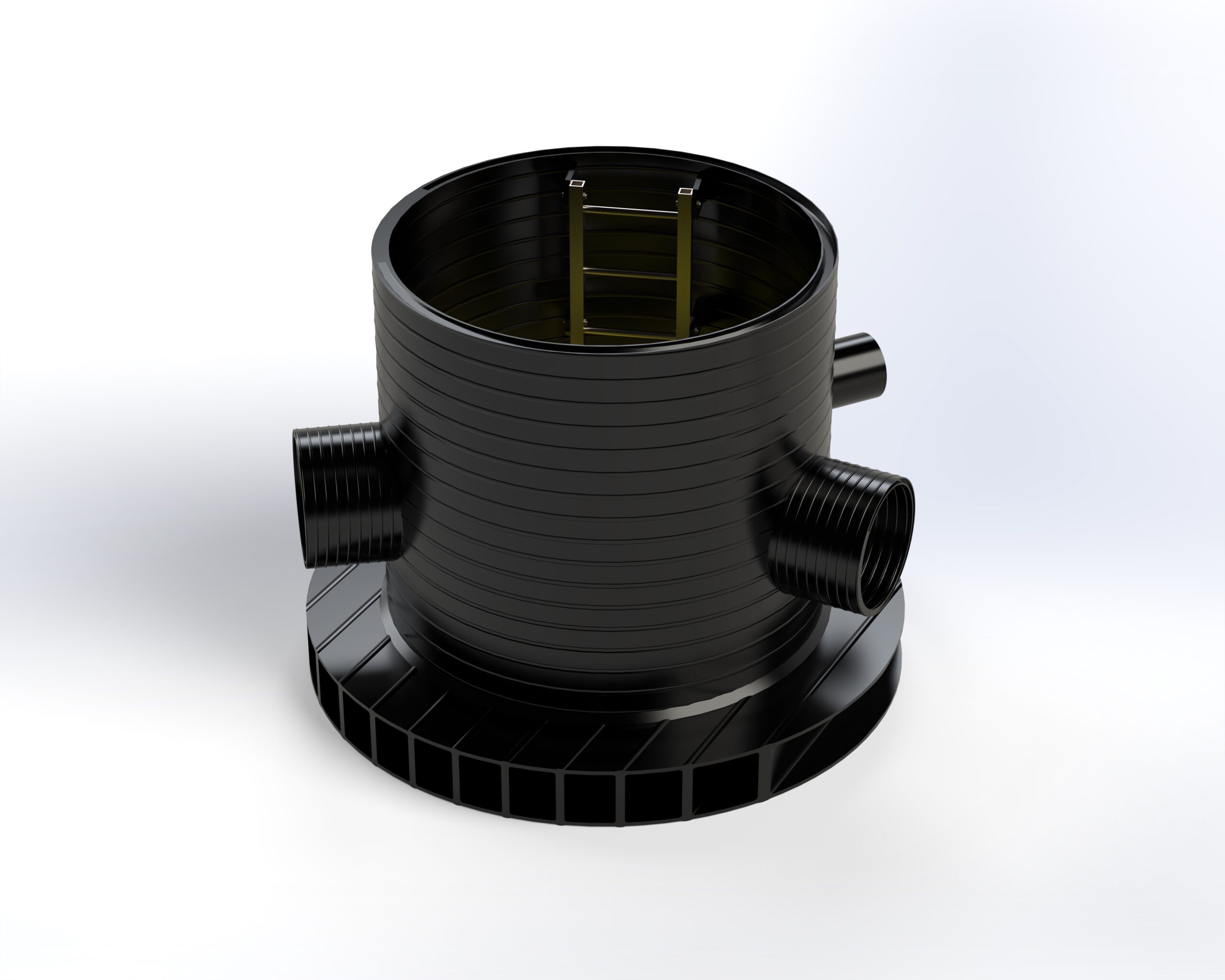

SDS supplied and installed an advanced wastewater storage system featuring a modular Weholite tank designed to integrate seamlessly with the existing infrastructure. The storage tank, constructed from Weholite panels, was engineered for durability and operational efficiency. The tank comprises upper and lower sections weighing 13 and 10 tonnes, respectively, with each section reinforced for strength and airtight integrity. Additional features include HDPE modular lifting eyes for precise installation, a walkway with handrails, and an emergency escape ladder for safe access.

This solution supported Anglian Water’s decision to modify its abstraction point outside the SAC, reducing reliance on Costessey Pits while maximising the capacity of existing storage infrastructure. Costessey Pits, which historically served as a bankside storage area for raw water abstraction, continues to play a crucial role in the scheme by providing a five-day raw water storage buffer. The project involved constructing an 8km, 800mm diameter pumping main to transfer raw water to Costessey Pits. From there, the stored water is conveyed to Heigham WwTW via the existing pipeline for treatment at a submerged ultrafiltration membrane plant. This approach allowed for a reduction in direct abstraction from the River Wensum while safeguarding long-term water supply resilience.

Results

Results

A new building will accommodate the new membrane ultrafiltration system, representing the largest submerged ultrafiltration plant in the UK with the greatest surface area of submerged reinforced membranes in Europe. The new scheme will increase supply to 57 million litres daily, treating 668 litres per second, and deliver a 62% reduction in operational carbon when compared to the original design by no longer requiring water to be pumped from Costessey Pits.

Taking just over two years to complete, and entering service at the end of 2019, this will represent the largest capital investment project within Anglian Water’s portfolio in AMP6, helping to ensure resilience of supply for decades to come, while protecting the local environment around the River Wensum, also a designated Site of Special Scientific Interest.

We’re planning decades into the future with this investment. This technology is vital to keep pace with the growing city’s needs. Norfolk is expected to be home to more than one million people by 2034 and many of those people will be coming to live and work in Norwich. This, combined with being in one of the driest counties in the UK, means that significant investment is needed to ensure we keep taps running and continue to power the economy. As importantly, this scheme will make sure the environment does not suffer because of future growth and is ready to cope with any increased demand on local water resources too.

– Paul Naylor, Regional Supply Manager, Anglian Water

Real world impact

M3 Junction 2, Surrey

SDS Aqua-Xchange™ prevents pollution of water bodies adjacent to London-bound M3 motorway

Holywell Row, Suffolk

SDS stormwater storage system brings to an end years of flooding endured by villagers.

Howden, Yorkshire

SDS addresses the impact of the town’s expansion on surface water control.

Need advice or a quote?

Please contact us to discuss how SDS might meet your project’s requirements.

Get in touch