Hookstone Road, Harrogate

Overview

The existing Combined Sewer Overflow (CSO) chamber at Hookstone Road in Harrogate, North Yorkshire, was equipped with upstream and downstream storage provided by large diameter pipes. During storm events restrictive pipe diameters and routing caused the pass forward flow to partially fill the storage pipes before excess flows were screened at the CSO chamber and discharged to the adjacent watercourse, often leading to blockages of the outlet sewer and resulting in unrestricted pollution of the receiving watercourse.

What We Did

SDS designed and installed a new CSO spill prevention system using large-diameter Weholite pipes and manhole chambers. A total of 184m³ of additional sewer storage was created with Weholite pipes placed upstream of the CSO, along with 360 metres of sewer upsized to 450mm diameter, and replacement of the existing restrictions downstream of the CSO. Online storage with a capacity of 730m3 is provided by 4 legs of 1400mm diameter, 120 metre long Weholite pipes, which were delivered to the site in units up to 10 metres long and internally welded together in situ. Weholite devices were chosen for their lightweight construction and ease of installation.

Results

The off-site fabrication approach significantly shortened the construction timeline and contributed to a 66% reduction in carbon impact due to less material transport and waste production. It also facilitated a high quality installation, thereby reducing the risk of future re-work.

Installation of each prefabricated manhole reduced the construction duration by 4 days compared to traditional in situ construction for a 6 metre deep chamber. Despite challenging conditions, including wet winter weather and clay soils, the project was completed efficiently and with minimal environmental impact. The new system successfully enhances sewer storage and flow, improving the protection of the local environment from pollution.

New, off-line manhole chambers were identified as an opportunity to utilise off-site fabrication and a variety of products were considered. Weholite high density polyethylene (HDPE) chambers were chosen for the scheme as they provided a number of significant unique benefits.

– Flora Keen, Technical Lead, MMB

SDS Products

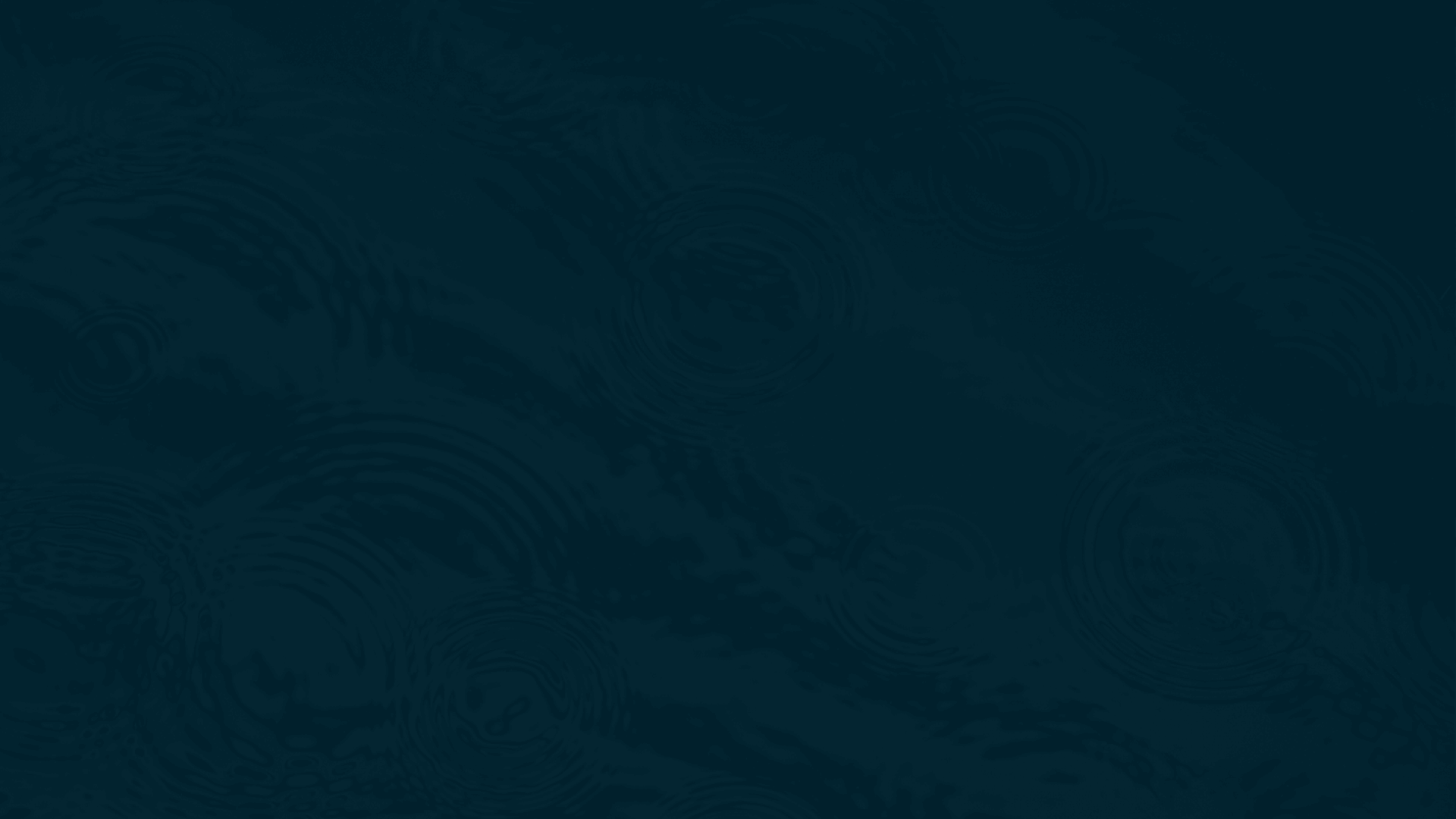

SDS Weholite Manhole

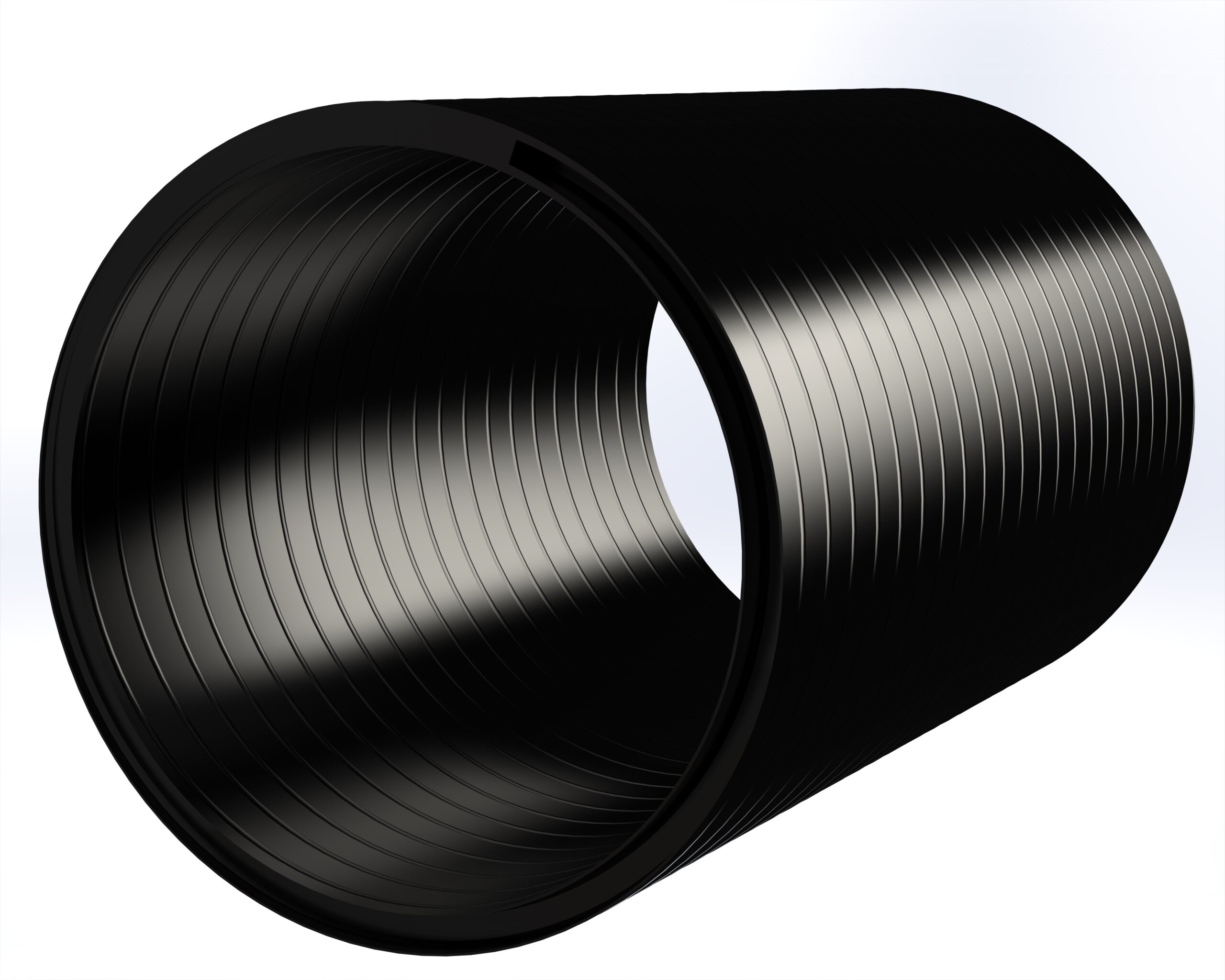

SDS Weholite Pipeline System

SDS Weholite Systems For Jointing

Real world impact

M3 Junction 2, Surrey

SDS Aqua-Xchange™ prevents pollution of water bodies adjacent to London-bound M3 motorway

Holywell Row, Suffolk

SDS stormwater storage system brings to an end years of flooding endured by villagers.

Howden, Yorkshire

SDS addresses the impact of the town’s expansion on surface water control.

Need advice or a quote?

Please contact us to discuss how SDS might meet your project’s requirements.

Get in touch