SDS Weholite Pumping Station

Key Benefits

Weholite Pumping Stations

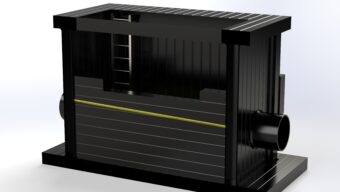

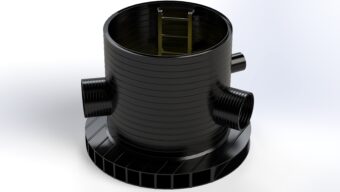

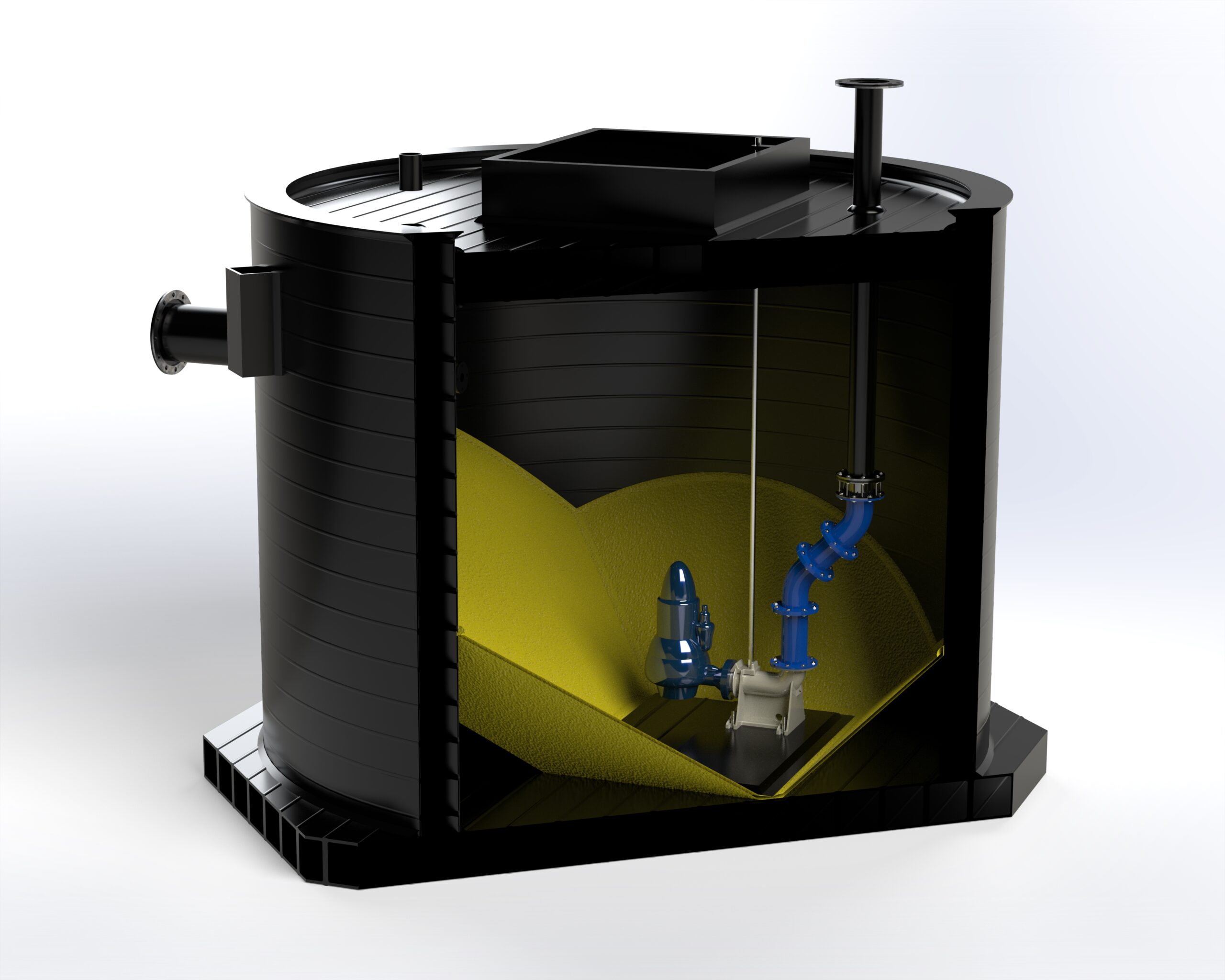

Pumping Stations are manufactured to varying depths using Weholite pipe and/or flat panel and fully assembled with all internal pipework and valves at our factory in Newport, South Wales. The use of Weholite lends itself to bespoke engineering designs therefore reducing the need for site-built solutions that have long programme times.

The pumping stations are designed to meet project specific requirements using a standard set of components; this improves site productivity, reduces installation time and construction materials, and provides major savings on programme costs. Weholite modular structural bases help counter groundwater and flotation, removing the requirement for a concrete surround in the majority of cases and contributing to significant improvements in system reliability and reductions in operational running costs.

Features and Benefits

Manufactured to varying depths and assembled off site.

Improves site productivity, reduces installation time and construction materials, and provides major savings on programme costs.

Available in sizes from 900mm to 3500mm.

Provides a huge choice of sizes sufficient for almost all applications.

Factory-fitted HDPE benching arrangement.

Provides ideal operating environment, reducing the potential for blockages and improving the station’s long-term reliability and design life.

Designed in line with Sewers for Adoption and/or specific water company requirements for S104 adoption*.

Meets critical industry requirements.

Ready to use immediately.

Enables super-fast connection and operation.

Anti-slip benching factory-fitted.

Ensures safe movement within the pumping station.

Designed to resist groundwater pressures.

Improves system reliability.

Concrete surround not required.

Saves time and cost and improves carbon footprint.

Resistant to impact, abrasion, corrosion, UV- and environmental deterioration and hydrogen sulphide H2S.

Can be used in harsh conditions and difficult locations.

Housing sector specific solutions designed in partnership with PDAS (Pump Design and Services).

Helps housebuilders and developers to provide solutions ready for adoption by the Water Companies.

Environmentally friendly production.

Non-toxic with a lower carbon footprint.

Industry Compliance and Accreditation

Weholite products meet, comply with and often exceed the applicable standards required by industry.

Weholite products are manufactured and certificated to meet the material and performance requirements of BS EN 13476: 2007 (Part 1-3) Plastic Piping Systems for Non-Pressure Underground Drainage and Sewerage.

Weholite piping is WRAS-approved; Weholite is “Approved for Use in Public Water Supplies” under DWI Regulation 31 reference nos. DWI 56.4.513a and DWI 56.4.513b.

Weholite piping, including welded joints, in diameter from 900mm to 3500mm meet the requirements set out in WRc Assessment Schedule PT/412/1117-AS and are certified by WRc.

Weholite systems, including any welded joints, are certified by Kitemark. Licence no. KM 560128 covers the manufacture of Weholite pipes, fittings and joints from DN400 to DN3000 diameter.

Weholite pipe systems from 450mm to 3500mm internal diameter are approved for use by Highways Authorities in England, Wales, Scotland and Northern Ireland as drainage structures (open ended and offline/online attenuation structures for surface and fluvial water).

Copies of the BBA HAPAS Certificates can be downloaded below:

Information Download

Product FAQs

More Products

Get in touch with us

Address

Clearwater House, Castlemills,

Biddisham, Somerset,

BS26 2RE,

United Kingdom